Pipe bends are used in many industries, including chemical, oil and gas, electric, metallurgy and shipbuilding. Pipe bends function as structural passageways to facilitate the transfer of substances, such as water and fuel. Some have a short radius while others have a long radius. Long radius bends give less frictional resistance and allow for less pressure drop when compared to short radius bends. When selecting the type of pipe bend, it’s important to choose one that is compatible to the application.

The Radii of Bend Pipes

Bend pipes come in all types of radii, including 3D bends, 4D bends, 5D bends, 8D bends and 10D bends. The radius in 5D bends is five times the nominal diameter. With a 10-inch diameter pipe, the radius of the centerline of the bend would be 50 inches. Pipe bending for the specified radii is both art and science. And with today’s modern machines and advanced software, pipe bending is highly precise. With the right machine, lubrication, tooling and material, achieving the perfect bend is a sure thing.

The Differences Between Bends and Elbows

Although the words bends and elbows are often used as synonyms, there are some differences. Bend is a term for any offset of direction in the piping while elbow is an engineering term. Elbows have limitations to angle, bend radius and size. Most angles are either 45 degrees or 90 degrees. All other offsets are specifically pipe bends. And while elbows have sharp corners, bends never do. The most basic different between a bend and an elbow is the radius of curvature. Bends have a radius more than twice the diameter, and elbows have a radius of curvature between one and two times the size of the pipe’s diameter. All elbows are bends, but not all bends are elbows.

Induction Bending for Creating 5D Bends

Induction bending is one of the means of bending pipes for 5D and other bends. Local heating, using high-frequency induced electrical power, is applied. An induction coil is placed around the pipe and heats a circumferential area of the pipe at a temperature between 850 to 1100 degrees Celsius. When the right temperature is reached, the pipe moves through an induction coil while an arm applies the bending force. There are many benefits to induction bending. It allows for large radii for smooth flow of fluid, reduces the number of welds in a system and fabricates bends quickly. With faster production, efficiency is ramped up. It’s also a clean process, as no lubrication is needed, and water is recycled.

Ram-Type Bending

Ram-type bending is an old and effective bending method for bending pipes, including 4D bends and 5D bends. This method is often used in muffler shops. It’s also one of the least expensive ways to bend pipe. A hydraulically driven ram forces the pipe against pivot blocks or rollers. Often, a ram tool is used to produce a concave surface and to prevent stretching on the exterior of the bend. The only downside is that ram-type bending is not as controllable as other methods.

Roll Bending

Roll bending is commonly used for pipes in the construction industry. Rolls are positioned vertically or horizontally to produce very large radii. The pinch-style roll bender is one of the machine types used for roll bending. A tube feeds between the lower and upper roll to produce the wanted bend angle. Some applications may require an additional roll to guide the tube outward when the coil is being formed.

Mandrel Bending

The mandrel bending pipe method is effective when the least amount of deformation is desired. The pipe is supported with a mandrel support to bend the pipe. The pipe is drawn through a counter bending die for further bending. This method of pipe bending is used in the manufacture of heat exchanger tubing, dairy tubing and exhausts like turbocharger and custom made ones. This method produces a non-deformed diameter every time.

Rotary Draw Bending

Rotary draw bending is often used for bending pipe when a constant diameter and good finish are desired. The pipe is drawn through a stationary counter-bending die onto a fixed radius former die. It’s used for roll cages, stock car chassis and other types of pipes.

Centerline Radius, Outside Diameter and Wall Thickness

Centerline radius, outside diameter and wall thickness are important variables with bending pipe methods. Plus, every pipe schedule has a nominal wall thickness. And since wall thickness can vary, any variations need to be accounted for. Other bending variables include the neutral line, outside bend radius and inside bend radius. Pipes experience spring back after bending. The harder the pipe and small the bend’s centerline radius, the more spring back, which results in radial growth. Copper pipes have less radial growth than steel pipe due to its less spring back. In pipe bending, consistency, size and quality of the weld seam matter for centerline radius, outside diameter and wall thickness. When these are right, the perfect bend can be created.

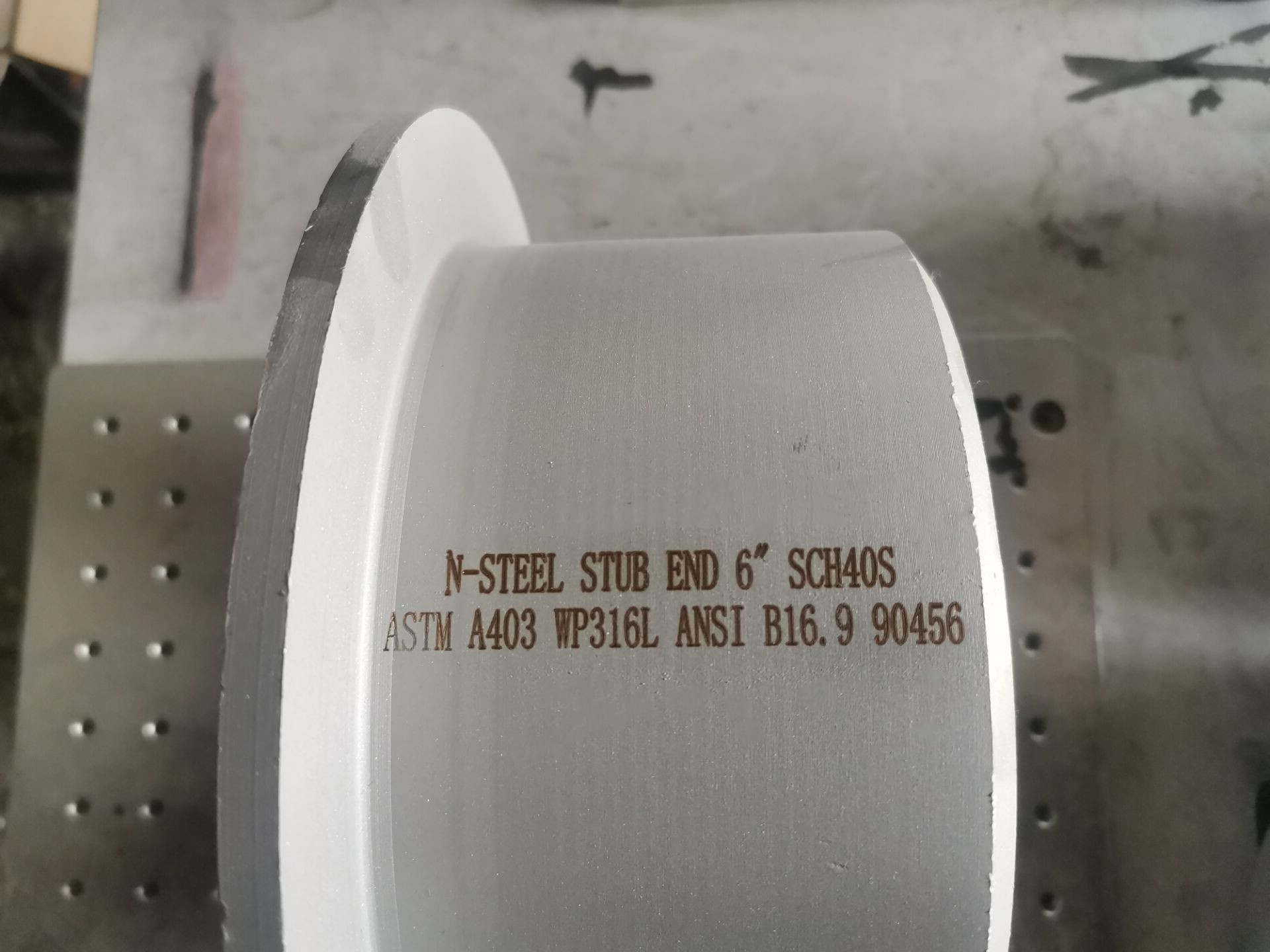

Material Used for 5D Bends, 6D Bends and Others

Common materials used for pipes and pipe bends include carbon, stainless steel, titanium, aluminum and cast iron. There are also plastic pipes of various grades. It’s important to select the right material for the right application, including the pipe fittings. Pipe fitting materials include aluminum, brass, bronze, cast iron, vitrified clay and many others. Pipe fittings must satisfy many criteria. The materials must be compatible with the fluids being transported, different pressure levels and fluctuating temperatures. Materials should also conform to certain standards like DIN, ASME, NPT and BSP. Surface finish is also important, and pipe fittings should have a corrosion-resistant property.

In some fields, the schedule 40 and schedule 80 are used for pipes. However, there are many other schedules due to increased pressure demands. The schedule of a pipe refers to its pressure rating. The higher the schedule, the higher pressure it can have. As the schedule increases, the wall thickness increases. When choosing pipe bends, it is critical to consider the schedule of the pipe. Schedule 80 is often used for heavy-duty while schedule 40 is often used for light-duty. Be sure to choose the appropriate schedule for the pipe bend, and it will be a perfect match.

more details,email to sales2@bdpipefitting.com .visit bepipefitting.bossgoo.com