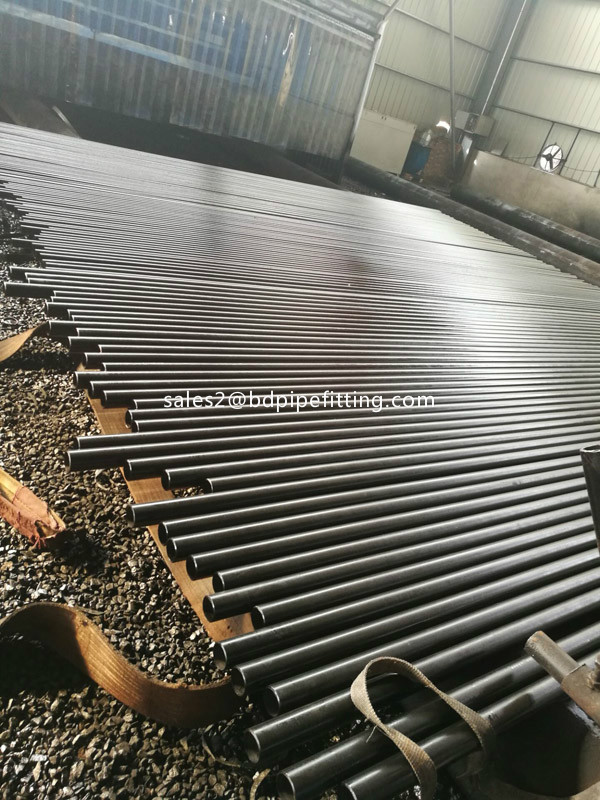

Baidu knows:how seamless steel pipe are produced

August 27, 2018

A large diameter alloy seamless steel pipe production process. It includes the following steps: Step one, material preparation; step two, tube heating and oblique rolling perforation; step three, trimming of the capillary; step four, thermal expansion deformation sizing; step five, heat treatment; step six, straightening; step seven , Inner grinding; Step eight, correction; Step nine, grinding; Step ten, inspection inspection; Step XI, and then finishing, final inspection and packaging. The invention can not only produce high-grade alloy seamless steel pipes within the range of large groups, but also has relatively small investment, high product quality, high production efficiency and low production cost. The main production process of seamless steel tubes Tube billet and billet heating, perforation of tube blanks, extension of steel tubes, rolling of steel tubes, sizing and reducting of steel tubes, cooling and finishing of steel tubes, or thermal perforation of steel blanks A method for manufacturing a seamless steel tube is characterized in that: a rolling stand having a plurality of rolls is arranged and continuously arranged in mutually different rolling directions. In the mandrel mill, the seamless steel pipe is rolled on susured at a plurality of points. According to the measurement result, at least the cores arech a manufacturing line, and the thickness of the steel pipe in the circumferential direction after rolling is mea respectively controlled. The end of each axis of the roll of the final rolling stand of the bar-type seamless mill is positioned so as to minimize wall thickness unevenness.

Source: 51 Steel Tube Net