Flanged all-welded ball valve steel is a good energy-saving environmentally friendly products, which features the valve when the internal leakage of leakage can be achieved "zero leakage" state, can make the loss of energy loss to a minimum. Greatly improve the energy saving and thermal measurement accuracy. The valve consists of an all-welded body and a carbon-reinforced Teflon gasket that can be operated frequently and run long life with impurities and chemicals.

Full welded flanged ball valve size structure

Full welded flanged ball valve size structure

Flange steel welded ball valve standard specifications

Pressure rating: 1.6MPa ~ 4.0MPa

Product Specifications: DN15 ~ 1000mm

Material: ST37.8, forged steel A105

Applicable temperature: -29 ℃ ≤ t ≤ 150 ℃ (with the valve body material and sealing surface material temperature difference is different)

Body material: cast steel, stainless steel, forged steel

Body: Steel Q235A

Sphere: stainless steel SS304

Valve stem: stainless steel 2Cr13

Valve stem seal: FPM

Ball seal: carbonized PTFE

Handle: DN15-DN200 plated carbon steel, for ≥ DN200, we recommend using a manual worm gear

Connection method: flange / welding connection

Drive: pneumatic, electric, manual, worm drive and so on.

Flange steel welded ball valve Applications:

1) City gas: gas output pipelines, main lines and all feeder pipelines.

2) Centralized heating: large-scale heating equipment output lines, main lines, branch lines.

3) heat exchanger: the pipeline and the loop hoist.

4) Steel plants: all kinds of fluid pipes, exhaust pipes, gas and heat supply pipes, fuel supply pipes.

5) all kinds of industrial equipment: all kinds of heat treatment pipes, all kinds of industrial gas and heat pipe.

Applications: Heating systems, heating areas, industrial pipes and other purposes.

Full welded ball valve performance:

1): Does not require maintenance, adjustment and lubrication, easy to install, long-term reliable operation at low operating costs. Surface spray processing technology, beautiful gloss, the country has been in the collar

First level. There will be no external leakage and so on. The valve body is welded so the valve is light and easy to insulate. Install adjustment mechanism, very simple, the operating handle can be

Remove, change to install.

2): Since the seat is made of carbon fiber reinforced Teflon seal ring and disc spring, it has strong adaptability to the changes of pressure and temperature and does not affect the pressure and temperature range

Any leak will result.

3): The processing of the ball has advanced computer detector tracking test, so the ball of high precision machining.

4): As the valve body material with the same pipe material, there will be no stress, it will not be due to earthquakes and vehicles through the ground when the deformation, the pipeline anti-aging.

5): the whole all-welded, equal diameter and diameter channels, the use of fixed ball and floating ball, dual piston sealing system, automatic

Inject sealant bearing.

6): In order to prevent static electricity, the valve stem and the ball, as well as the valve stem and the stuffing box with a ball and a spring respectively, can keep all parts of the valve and the valve body conduct electricity to pass the current

Area, release static electricity. Not only to prevent fire, but also to prevent corrosion, to achieve a temporary cut-off, so that timely maintenance.

7): Valve stem off function because the valve stem pressure by the valve, the total force from the stem so the stem designed to prevent structure.

8): With low friction material thrust washer support to push the pressure to the valve stem, the valve stem only play the role of torque transmission.

flange type:

Blind Flange

Slip On Flange

Spectacle Blind Flange

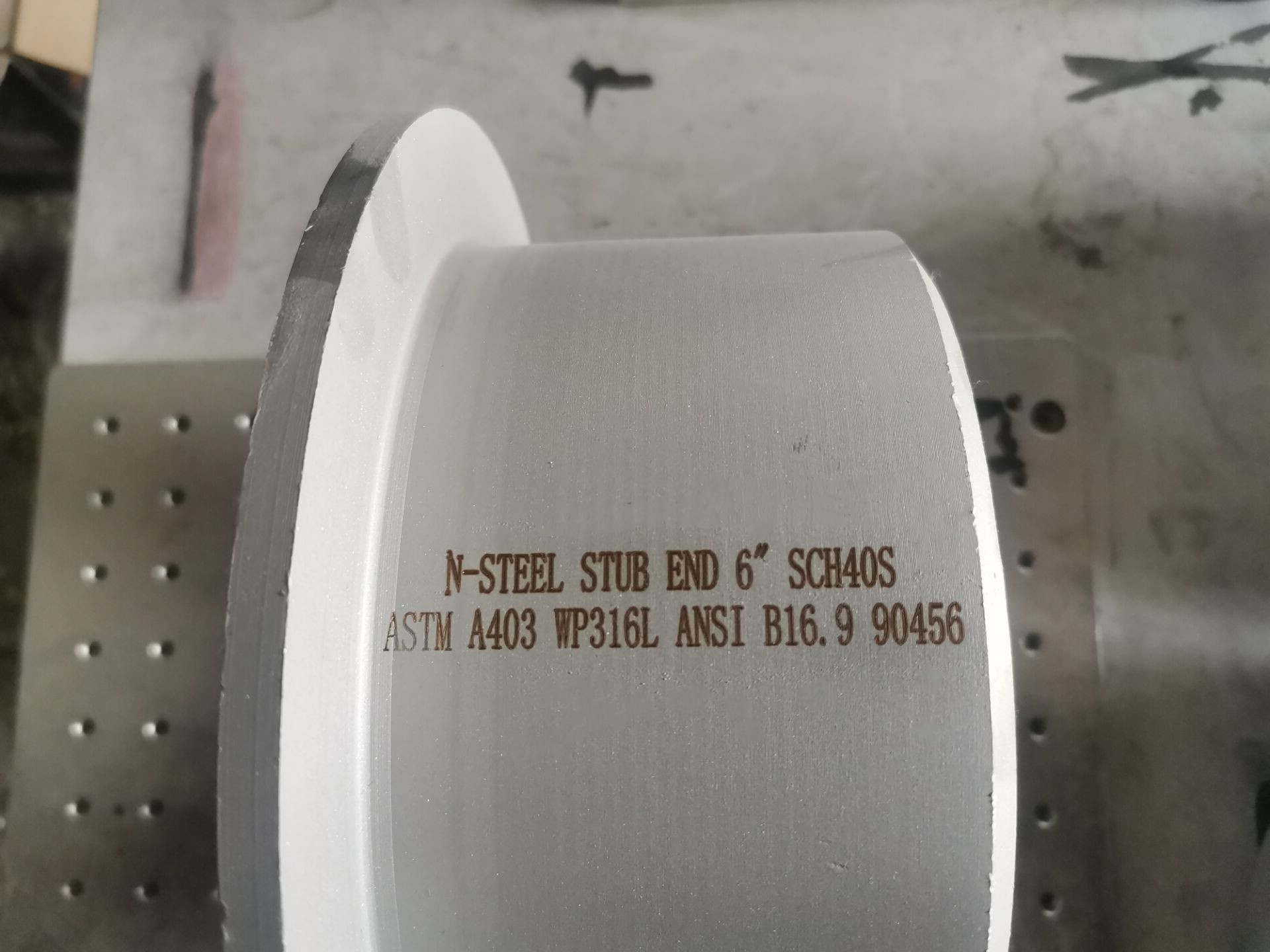

Lap Joint Flange

Weld Neck Flange